Our niche

Unique products. Unique knowledge.

Our products and expertise provide improved manufacturing processes, lower energy consumption and a better work environment.

Download our new catalog

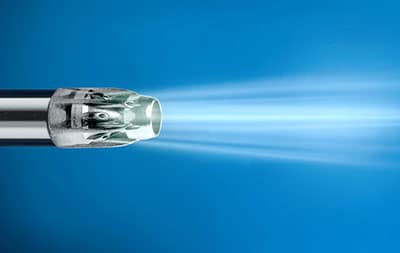

Unique research and technical expertise in the field of compressed air dynamics. Browse our products that help manufacturing companies to optimize energy consumption and improve the work environment.

Contact us

We’ll be happy to help! Complete the form below and we’ll get back to you shortly.